I used to work in the engineering department of a manufacturing company. I was

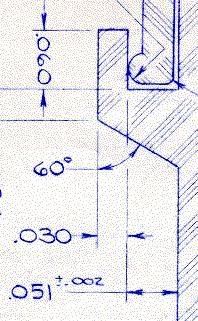

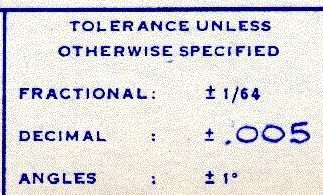

a draftsman, creating mechanical drawings for the shop. To allow for the

inexactitudes of man and machine, the dimensions given for each machine part

would include an allowable variation - a tolerance. Establishing the correct

tolerance for each dimension was an important consideration. Calling for more

precision than needed would slow down production and drive up costs.

Conversely, allowing too much variation would result in ill-fitting parts and

a poorly functioning assembly.

I used to work in the engineering department of a manufacturing company. I was

a draftsman, creating mechanical drawings for the shop. To allow for the

inexactitudes of man and machine, the dimensions given for each machine part

would include an allowable variation - a tolerance. Establishing the correct

tolerance for each dimension was an important consideration. Calling for more

precision than needed would slow down production and drive up costs.

Conversely, allowing too much variation would result in ill-fitting parts and

a poorly functioning assembly.

This engineering concept of tolerance always seemed to correspond well with

its general definition elsewhere. Namely, it was usually acknowledged that

nobody is perfect,

that it's unreasonable to expect absolute adherence to codes of conduct, so

let's cut each other a little slack now and then.

that it's unreasonable to expect absolute adherence to codes of conduct, so

let's cut each other a little slack now and then.

Lately, however, lots of folks are referring to tolerance as if it means that we can no longer hold to any standards at all, that any behavior must be accepted and even approved. Surely such a definition bears no similarity to its original meaning.

If a car manufacturer were to adopt such a definition of tolerance, their vehicles wouldn't run very well. I doubt that you'd even be able to drive them from the dealer's parking lot.

No comments:

Post a Comment